Scanning Electron Microscopy in 失效分析

专职专家

丹尼尔KiedrowskiDaniel has extensive experience in performing 失效分析 and routine product evaluation of components and assemblies for the 运输 sector.

什么是扫描电镜?

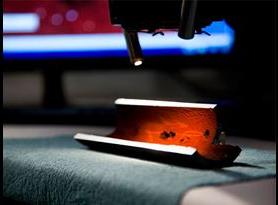

Scanning electron microscopy (扫描电镜) is an invaluable tool in conducting 失效分析 of metallic and non-metallic components and is used in some capacity in a large percentage of the investigations performed by im体育APP. The 扫描电镜 is a powerful tool in determining the origin(s), 模式, and direction of propagation of cracks or fractures. 扫描电镜 is used in conjunction with detailed documentation via macro photography and stereomicroscope to give a complete representation of the features or components being examined.

扫描电镜 is also employed heavily in the evaluation of debris, 粒子, 残留, 腐蚀产物, and other features requiring high magnification examination. The necessity and versatility of these instruments are evidenced by their presence in numerous im体育APP laboratories company-wide.

扫描电镜是如何工作的?

An 扫描电镜 operates by bombarding the surface of a sample with a focused beam of electrons. The electron beam excites the electrons of the material, resulting in the release of additional, 二次电子. 另外, the electron beam can be backscattered by the sample and reemerge from the sample surface. Both secondary and backscattered electrons can be collected and displayed to provide an image of the surface being evaluated. The former provides greater resolution of surface features and the latter reveals greater topographic surface detail and information regarding the atomic weight of the surface being evaluated. Each type of electron plays a specific role in analyses via 扫描电镜 depending on the objectives of the evaluation.

扫描电镜适合你吗?

The chief advantage of an 扫描电镜 in 失效分析 is that the resulting image is generally similar to that of an optical photographic, but with significantly greater depth of field. 扫描电镜 also allows examination at magnifications ranging from approximately 5X to greater than 50,000X, permitting documentation of large regions of a sample and microscopic features without changing instruments or lenses. The primary disadvantage of 扫描电镜 is the lack of color imaging, which reinforces the importance of sample documentation via standard optical photography methods in conjunction with 扫描电镜. Examined samples must also be electrically conductive, although conductive surface coatings and the use of an 扫描电镜 with a special variable pressure sample chamber and electron detectors mitigate many of these issues.

An extremely useful side effect of bombarding a surface with electrons is the generation of characteristic X-rays by the atoms of the material due to excitation by the electron beam. These X-rays can be detected and quantified by an energy-dispersive X-ray spectrometer (EDS) attached to the 扫描电镜. EDS provides the relative chemical composition of surfaces and features being examined using the 扫描电镜. This information can be extremely useful in the identification of 腐蚀产物, surface 残留 or contaminants, 材料夹杂物, wear debris and a host of other features that may not lend themselves to other conventional chemical analysis techniques. EDS results can also be combined with 扫描电镜 images to form elemental EDS maps that provide a graphical representation of the distribution of elements in the surface or feature being examined.

To learn more about Scanning electron microscopy (扫描电镜), or if you have any questions, 今天就im体育APP的团队.

找到相关的 资源

来自im体育APP的更多信息

失效分析

Find out how im体育APP's global team of 失效分析 experts learn from the past, to help prevent future failures in service.

X-Ray Fluorescence (XRF)

XRF analysis is a non-destructive analytical technique used to determine the elemental composition of materials.

Scanning Electron Microscopy (扫描电镜)

扫描电镜 analysis is a powerful analytical tool which uses a focused beam of electrons to produce intricate, high magnification images of a sample’s surface topography.

Polymer 失效分析

im体育APP experts are here to help you with your 失效分析 on plastics, 复合材料, 橡胶, 粘合剂, 密封剂, 油漆和涂料.